Is your Remington 700, Winchester 70, Weatherby MkV, Howa 1500, Tikka T3, Mauser 98 or Savage 10/110 having problems holding a zero in all weather? Tired of those odd fliers that open up your groups? Sub-MOA on Saturday and all over the paper on Sunday? Drop it into aluminum and quit wasting money testing load after load!

What's all the fuss over Aluminum Bedding? Aluminum doesn't move or compress, shrink or expand like wood and plastic. This is important both while the stock is being made as well as when you use it. It doesn't rot, soften or become brittle with age nor will it soak up solvents like a sponge over the years. Climate or temperature won't affect it. Read on and we'll explain ...

Aluminum is more precisely machined than wood or plastic. When a wooden stock is being cut, the tools being used (especially if they are not sharpened frequently) can crunch, gouge and yank wood fibers from the wood, resulting in a less-than-perfect inlet.This is why you frequently see slivers of wood sticking up in the very areas that are supposed to be the most precise, under the receiver. This results in high and low spots and reduced accuracy. When a plastic stock falls out of the hot mold it changes shape as it cools. Mold engineers make calculations and complicated cooling fixtures to accommodate this as best they can, but it is never perfect because different parts of the stock will always harden at different rates. Also, mold temperatures rise and fall with production rates, slight product variations are the result. This all affects the way a plastic stock's mating surfaces supports the receiver and the barrel.

Aluminum doesn't compress like wood and plastic. You know that squishy, sponge-like feeling you get when you tighten the receiver screws? How much is enough? When you tighten the screws on a wood or plastic stock, you are actually compressing the material between the receiver and the floorplate like a sponge. This means you cannot tighten them evenly or as tight (25 vs. 65 in/lbs) as aluminum and the forces resulting from firing the rifle may actually alter the bedding (therefore your zero and your accuracy) over time. Ever notice your screws are loose after you shoot? Recoil pad not fitting like it used to? It's not the screws backing out, it's the material compressing under the torque and recoil stresses of firing.

Aluminum doesn't shrink or expand like wood and plastic. Temperature and humidity are the enemies of both wood and plastic, but aluminum is hardly affected by climate. Wood stocks absorb and release humidity causing them to expand or shrink. For the same reason wood-frame windows stick in the summertime, the rifle you sighted-in last July is usually off-zero by November, or your bullet impact may change unexpectedly in the mountains, rain or snow. Wood and plastic stocks when frozen, left in the sun or rain can warp up, down and sideways, depending on the air that surrounds them and the even the side the sun beats down on them. This puts uneven pressure in the wrong place at the wrong time and often affects both accuracy and zero right when you need it most!

Modern plastics can be understood as simply a more solid form of another petroleum product, motor oil. It changes viscosity (softening and stiffening) constantly as the temperature rises and falls, causing your rifle to shoot differently from day-to-day, week-to-week and month-to-month as well. Also, as they age, gasses escape from the petroleum substrate and can cause other changes in its properties, commonly shrinking and brittleness. If you are suffering inconsistent groups this may be the culprit.

Aluminum isn't affected by gun cleaning solvents. Every year we see and hear about dozens of rifles wearing stocks that have been ruined by solvents from well-meaning riflemen keeping their guns clean. Especially when stored vertically in a gunsafe, residual oils in the barrel run down into the receiver and soak into the wood behind the recoil lug, under the tang and around the magazine, anywhere it can get. It not only softens but literally rots the stock. What's even worse is that these hidden areas often go unnoticed for years and eventually render the stock unfit for service, unable to be repaired. Imagine the problems this can unexpectedly cause!

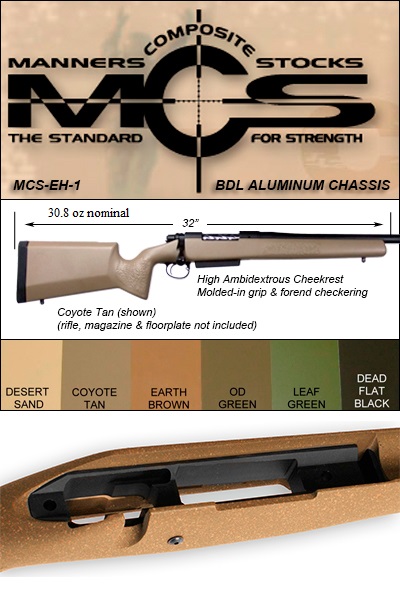

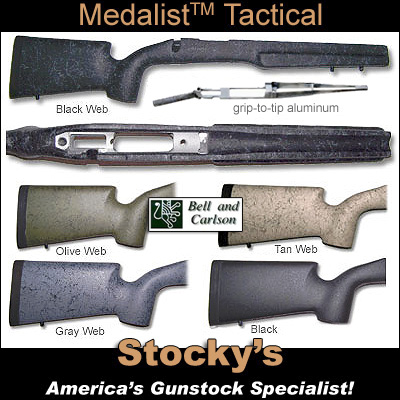

Installing an aluminum bedded stock cures these ills instantly! These are the same identical stocks major manufacturers use on their best rifles ... as well as many custom rifle builders. That's why they use them. A 30-minute, do-it-yourself upgrade to one of Stocky's® aluminum bedded stocks may be the simplest, easiest, quickest and most sure-fire way to improve any rifle's accuracy and ability to hold a zero, instantly. Professionals, casual users and advanced shooters, report results like this back to us all the time. And chances are Stocky's® carries the perfect stock for you, or your customers, in-stock!

Aluminum bedded stocks are simple to install at home! There's a reason the most expensive factory rifles are the aluminum bedded versions. Great for amateurs and pros alike, anyone that can turn a screw can install an aluminum bedded stock on their rifle. There are no special tools, fitting or talent required to replace your old stock with a new aluminum-bedded tack-driver on a standard factory rifle. No additional bedding work is necessary. If you're an accuracy professional or other perfectionist -- and do want to epoxy-bed or fit a custom barrel -- have at it! We have all the supplies to do so in-stock as well.