While many out-of-the-box rifles are very accurate and attractive, few offer the enjoyment and none that feeling of accomplishment derived from completing that one special gun, perfectly suited for the intended task no matter if you plan on shooting targets, taking that long-awaited far-away hunt or ambushing a whitetail in your favorite management area. You likely have gained some experience, often years of experience and you know the expectations as well as the drawbacks of your current rifle and are now ready to take it to the next level.

While many out-of-the-box rifles are very accurate and attractive, few offer the enjoyment and none that feeling of accomplishment derived from completing that one special gun, perfectly suited for the intended task no matter if you plan on shooting targets, taking that long-awaited far-away hunt or ambushing a whitetail in your favorite management area. You likely have gained some experience, often years of experience and you know the expectations as well as the drawbacks of your current rifle and are now ready to take it to the next level.

The simple fact is that most factory rifles are compromises, conceptualized in the boardrooms and marketing departments, engineered for a certain cost to sell at a desired price point and designed to fit "the average shooter" whoever they believe that to be. Conversely, the custom rifle gives you the opportunity to move yourself to the next level by allowing you to choose literally each and every component, no matter how large or how small, and have it all assembled in a way that specifically suits the guy paying for it and the duties he will be expecting it to perform. This way the intermediate, advanced or professional shooter is able to remove as many variables as possible and greatly increase the odds of a successful outcome.

The purpose of this discussion is not to make those choices for you, it is rather intended to inform the reader of the parameters he has to choose from as well as the areas where his choices may be more complicated, limited or even non-existent. As the owner of America's gunstock specialist, I get calls every day from folks that have discovered, halfway through their build in many cases, that what the fellow thought he was going to make happen simply is not possible due mainly to the lack of suitable parts for what he had in mind. Conversely, many gunsmiths today don't have a complete comprehension of the possibilities available to accomplish the task desired. I hope the reader goes away with a sense of direction, a big picture plan if you will, of the next steps required to bring the perfect rifle to fruition.

Understanding The Components

Any bolt action rifle (or rimfire for that matter) is assembled from six fundamental components that may be selected individually, in the order it is wise to select them:

Any bolt action rifle (or rimfire for that matter) is assembled from six fundamental components that may be selected individually, in the order it is wise to select them:

- Receiver (action);

- Barrel;

- Riflestock;

- Trigger;

- Magazine;

- Triggerguard.

Each one of these components will be selected not only upon their merits individually, but also how well they work in concert with the whole picture. For example, though it is likely a person may be able to get the tightest groups with a 2 ounce trigger, you probably don't want to use one hunting elk in the canyon. Lets take up a discussion on each element and start assembling our parameters.

1. Receiver- Rarely does the custom rifle owner / builder start with a bare receiver, most of the time he or she gets a good deal on an entire rifle with the intention of removing the components that are targeted for replacement.

This is the biggie, not only from a functionality and accuracy standpoint, but your choice here can make or break the entire build, so you need to do your homework. It is not our job to debate the various pros and cons of each from an accuracy or quality perspective, you have your own feelings on this subject by now. The one thing I will say about choosing a receiver is, before you plunk down the scratch, make sure you can get the all the other components, especially the stock you want for it. A great example is if you want to build a heavy-barreled target varminter on the excellent Browning A-Bolt. Sure, a gunsmith can screw on a barrel and tweak the trigger, but you'll have a few years and a ton of money invested in paying a custom stockmaker. There are simply few after-market drop-in stocks available for anything but the light barrel versions.

Other receivers, though excellent from a mechanical viewpoint, that have few if any after-market stock options are the Browning BBR, Remington 788, 770, 710, any Mossberg rifle (except the 1500), Marlin rifles, Older tang-safety Rugers and the Yugo Mausers (the small and large ring Mausers are fine in many cases, just not the intermediate Yugo version). Look for stocks before you buy the barrel.

By far the best receiver from a parts standpoint is the venerable Remington 700 for a custom rifle of just about any kind. Most of the high-end custom bolt-action receivers are variations of the 700. Once you get away from the 700 the stocks, triggers and bottom metal (triggerguard and magazine options) disappear, but good choices do exist for the Savage 110 / 10, Winchester Model 70 and Weatherby Vanguard (a .k.a. Howa 1500.) This is about where the choices end, but as mentioned, if you have something in the house that you want to start a custom build with, do the parts homework before you begin. Stocky's Stock Finder at the upper-left of the site is a great place to do the initial search, most people tell us if we can't stock it the way you want, few if any others can. Plus many gunsmiths these days are primarily 700 or Savage specialists, if you are using something other that these be sure to do that homework up-front also.

Another important consideration when it comes to the receiver is the proposed cartridge you want it to house. Will it fit in a short action receiver, or will you be acquiring a long action? What will the bolt face (1a.) have to be? A .223 or .300 AAC takes a different bolt face than a .308, .300 Win Mag or ultra mag. Will the feed rails on the receiver work well with your desired chambering? If you can acquire a receiver specifically made for the cartridge head and length in question your build will be easier in many cases, but should you already have a receiver, or have your eye on a great deal for one, there are some very good options for adjusting it to function reliably with the intended chambering.

Another important consideration when it comes to the receiver is the proposed cartridge you want it to house. Will it fit in a short action receiver, or will you be acquiring a long action? What will the bolt face (1a.) have to be? A .223 or .300 AAC takes a different bolt face than a .308, .300 Win Mag or ultra mag. Will the feed rails on the receiver work well with your desired chambering? If you can acquire a receiver specifically made for the cartridge head and length in question your build will be easier in many cases, but should you already have a receiver, or have your eye on a great deal for one, there are some very good options for adjusting it to function reliably with the intended chambering.

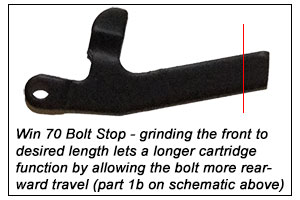

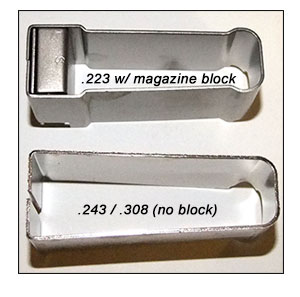

A receiver can be adjusted, via the modification, addition or removal, of any magazine blocks / spacers (part # 5 on schematic above) and bolt stops (1b.) and perhaps ejector (1c.), depending on the receiver, to work well with a variety differing length cartridges both longer and shorter than its original chambering. You may even be able to purchase the proper parts from the factory or liberate them from another rifle. This is valuable knowledge for the specialist.

As evidence of this many long action original factory rifles for shorter rounds were produced prior to the advent of a short action offering in their lineups. For example, the venerable Winchester Model 70 wasn't produced in a short action receiver until the 1980's. Same can be said of the earlier Savage 110's. In fact, many custom rifles intentionally use a long action with a short cartridge to allow the handloader the option of seating bullets a bit further out of the case, thereby gaining some powder capacity. This is typically done with rounds like the 6.5 / 284 and 7x57, where the shooter intends to load heavy pointed bullets for long range shooting.

As evidence of this many long action original factory rifles for shorter rounds were produced prior to the advent of a short action offering in their lineups. For example, the venerable Winchester Model 70 wasn't produced in a short action receiver until the 1980's. Same can be said of the earlier Savage 110's. In fact, many custom rifles intentionally use a long action with a short cartridge to allow the handloader the option of seating bullets a bit further out of the case, thereby gaining some powder capacity. This is typically done with rounds like the 6.5 / 284 and 7x57, where the shooter intends to load heavy pointed bullets for long range shooting.

Many short action receivers are also modified using various different parts at the factory for unusually short rounds, like the .223 Rem in that same receiver that would be a candidate for the .308 Win. In order to use the shorter cartridge reliably, they will spot-weld a piece of metal in the rear of the magazine box as well as use a longer bolt stop to align the front of the bolt face with the rear of the cartridge case. You can buy those parts from most factories or gunsmith supply houses, we may even have the mag boxes in stock.

ADVANCED BUILDING NOTES

Sometimes even a long action receiver has to be modified with parts and/or machining to accept an even longer round. A good example of this can be found when rebarreling a receiver previously set up for the standard belted rounds (.264 Win Mag, 7mm Rem Mag, .300 Win Mag, .338 Win Mag) to a full-length .300 Weatherby or .375 Holland & Holland magnum. In this case, the receiver itself will not be altered, but the distance the bolt is allowed to travel in the receiver can be lengthened by either machining the front off the bolt stop (and ejector) so that they allow the cartridge bolt to move further into the receiver in order to travel behind the rim of the case and therefore allow it to be pushed forward on closing, or simply replacing the bolt stop (and ejector) with the appropriate factory part. I recently had to do this on a Model 70 that was rebarreled from a .264 Win.

It is important to understand this process yourself and not simply leave it up to others, because many gunsmiths and "experts" do not understand the way all this functions together. In the case of my .375 outlined above, two very experienced gunnys with reputations for tack-driving accuracy did not know what to do. I finally had to call Winchester parts department and order the extractor and ejector, installing them easily by myself. The rifle now functions perfectly, and would have been a disappointment if I didn't have the answers.

How did I know? By understanding the parts in my receiver, knowing that Winchester made a lot of Model 70's in .375 H&H, and with the knowledge that Winchester only made two basic M70 receivers, long and short, even though I was told by many supposedly knowledgeable people they made an "extra long." I knew they made their long an "extra long" by shortening the stop and extractor, therefore lengthening the bolt travel, not by forging a different receiver. Learn what makes your rifle tick, don't leave these things up to anyone else or you may not be happy with the results. Give me a call if I can help.

Remington does the same thing with their Ultra Mags, but Remington uses a spring & plunger in the bolt face for ejection so no modification would be required. It's good to know this if you want to move into the Wyatt's XL Detachable Mag system for the Ultras and .338 Lapua, you will need to shorten the bolt stop to allow a bit more travel. Also, the Remington receiver always has a little projection, or "tab" at the rear of the magazine well, with a threaded hole designed to attach an ADL magazine. They do this on all receivers, even BDL's. That tab must be ground off to use the XL Wyatts and is a wise modification on any .338 Lapua build on the 700. Instructions are included in the Wyatts XL mag kit.

1b. Cartridge Bolt - Let's say you have a .308 Model 700 Rem that you wish to rebarrel to another round, before you make that final selection you must compare case head diameters. Any reloading manual will have cartridge dimensions, or you can look them up online by Googling ".308 Win cartridge dimensions", several sources will pop up. The critical dimensions are the overall length (for the receiver length necessary) and the rearmost extraction rim dimension. The latter is what is of concern to the cartridge bolt face.

As long as the desired cartridge has a rim diameter that within a few thousandths (perhaps + or - .002") your existing bolt face should be just fine. The important factor is the extractor, whether is embedded in the bolt face like the 700, or if its the claw-type as on a M70 or 77, can get a good grip on the rim to extract the fired round from the chamber.

As long as the desired cartridge has a rim diameter that within a few thousandths (perhaps + or - .002") your existing bolt face should be just fine. The important factor is the extractor, whether is embedded in the bolt face like the 700, or if its the claw-type as on a M70 or 77, can get a good grip on the rim to extract the fired round from the chamber.

If it's significantly larger or smaller, your gunsmith will have to open something up on a lathe to fit, they may simply be able to replace the extractor with another factory part, or in some cases, you may need to purchase a new bolt. Since some of the after-market bolts are so spiffy, I often elect to spend the money for a new bolt as a matter of routine. I use the bolts offered by Pacific Tool & Gauge with excellent results, plus I get to pick the model and type of bolt knob that screws on. Most gunsmiths I know are well aware of these options and can advise you.

ADVANCED BUILDING NOTES

When you are planning to move up or down the cartridge head classifications (like rebarreling a .308 to .223 or a .30-06 to a .300 mag), another area of concern, aside from the bolt face as discussed, is the feed rails on the receiver. The best way I know to overcome any potential feeding problems on ANY custom build is to go with one of the outstanding detachable magazine systems we offer. In so doing, the feed rails n the receiver are not modified in any way as the proper box magazine you will use has its own "center-feed" lips and you can be sure it will feed well when installed into the stock according to the instructions included.

This also applies to the factory rifles that have factory detachable, like the Rem 700 DM. Keeping a DM a DM is required as Remington mills the rails off the receiver because they know the magazine will have them. One cannot convert a Rem 700 DM to a BDL, ADL or anything that does not have some sort of detachable mag for this reason.

2. Barrel - almost any barrel blank can be installed on any receiver by a competent rifle smith.

Here you'll have a choice among brands: Douglas, Shilen, Hart, Krieger and Rock Creek are among the most highly prized today. I hasten to add that this is but a partial list, this day and age we live in often make availability the key factor as wait times can run over a year. Another choice you will make is the addition of a muzzle break to reduce recoil if desired.

Taper-wise (weight-wise) you have three general choices - featherweight, sporter and heavy barrels - with a myriad of variations. Choosing the barrel weight has the second-most influence over stock suitability after the action. This is the place to add or reduce the total weight or your build, not the stock. Most barrel makers have a "contours" page not unlike our contour page, with the weights listed. The vast majority of the rifles today are for long range, being built as heavy sporters (.70" muzzle), using the Remington Varmint taper (.85" muzzle), or the straight-tapered M24 (.90" muzzle with less taper than the varmint barrel).

The other thing to consider when musing over various barrels is the rifling type and rate-of-twist. There's a ton of research on this that you can pull up online, but remember everyone has their own ideas. The U.S. military and a lot of folks building long range hair-splitters are opting for the 5r mil. spec. M24 .308 11.27" twist barrels we carry from Rock. There are three reasons for this: 1. The M24 taper shoots as well as a full-bull (no taper) with a lot less weight; 2. The 5 grooves is believes to put less pressure on the bullet, allowing a smoother transition from the leade to the lands, and; 3. the .308, 11.27" twist is perfect for the current crop of 147-168 grain match bullets, yet will stabilize most 180's. 1 turn in 10" is the standard, and is the best choice for shooting anything from 180 though the heavy Berger VLD's. The 6.5mm 1-8" twist comes in a close third in popularity due to the latest crop of .264 bore cartridges (6.5 Creedmore, 6.5 / .284 Norma, .260 Rem.)

Again, your choice of barrels has a lot to do with the stock you want. As mentioned, while its easy to get an A-Bolt re-barreled to fit the Bell & Carlson Ultralight stocks, you have to keep it something similar to the factory dimensions or you'll lose the forend flats when fitting it in.

3. Stock - this whole site is devoted mostly to stocks, so we won't hold you up very long here.

We strongly recommend choosing the stock before proceeding, not because we want you to buy one from us (we do, but that's not our primary concern here), but because we hear from guys every day that are half-way done and can't find a stock that will easily fit their build.

4. Trigger- there's many after-market options for the mainstream receivers, almost none for the others. Of course, you or your gunny can lighten and/or smooth out the existing one. When you are ready to move into a Jewel Trigger, you'll know why. Until then for most sporting applications the Remington 700 and the Savage AccuTrigger are at the top of our list. Other receivers that come with exceptional triggers with a lot of adjustment potential are the Winchester Model 70 and the older Sako, the A-Series (A-III, A-IV, etc.).

5. Magazine - we put magazine before triggerguard because of the new detachable magazine systems we carry. The H-S Precision is the best hunting system, the Wyatt's DetMag (M4) works great in Bell & Carlson stocks and other standard 700's and there's a new Weatherby Vanguard version coming if it's not here already. The M5 profile is by far the most popular for heavy-rifle builds using McMillan or Manners stocks.

I'll go so far as to say that anyone building a custom Rem 700 is well advised to replace the existing magazine / feeding system with one of the new detachables. The H-S Precision version is the best choice for hunting and a great choice for anything, the Wyatts and M5 Stealth are best on target, varmint and tactical rifles.

Aside from a detachable mag system, of course one may opt for the more conventional hinged-floorplate or blind magazine set-up. These are most popular on hunting rifles. Obviously your choice of magazine will dictate the last major item you choose.

6. Triggerguard - main choice in conventional triggerguards are the style and whether you want to save weight with aluminum or go with the bulletproof steel units.